Grape must cooling systems

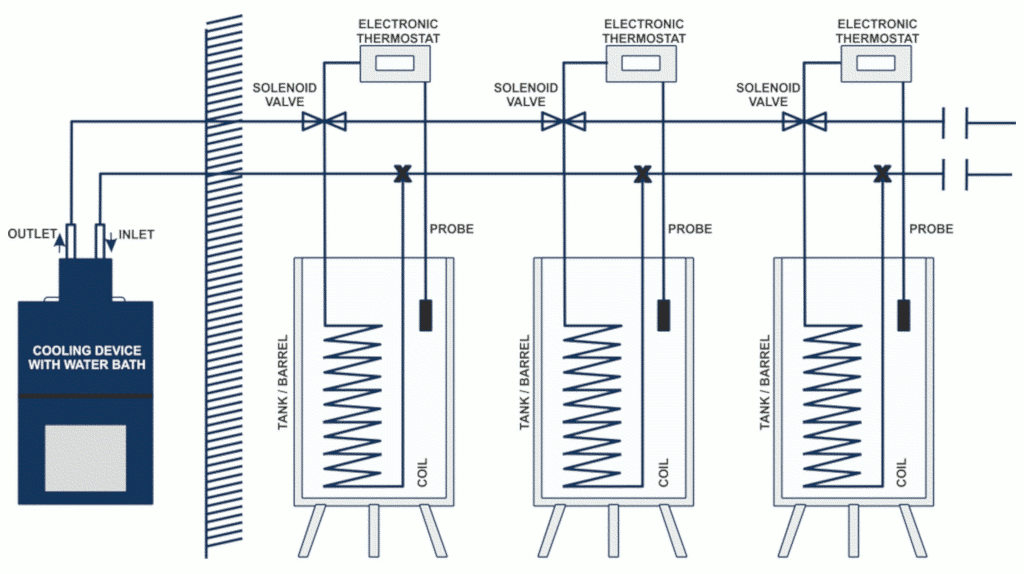

We also make systems for controlling the fermentation temperature of must, which are adjusted to 6,000 liters, regardless of the number of tanks. Temperature control using solenoid valves and electronic temperature controllers very precisely maintains the desired temperature in each tank separately. The system is adapted for easy handling and monitoring of tank temperatures. Controlled fermentation protects the aromas in the must, thus achieving a higher quality of wine.

Each undercounter cooling device with water bath from our program can be used for controlled fermentation of must. For volumes up to 3,000 liters, we recommend appliances from our standard program.

For cooling volumes above 3,000 liters send us an inquiry.

We recommend that the installation of the controlled fermentation system be performed by an authorized person or a refrigeration service technician.

ECO S VE2

For cooling up to 3 tanks,

maximum 1,000 liters.

ECO L VE4

For cooling up to 4 tanks,

maximum 2,000 liters.

ECO XL VE6

For cooling up to 6 tanks,

maximum 3,000 liters.

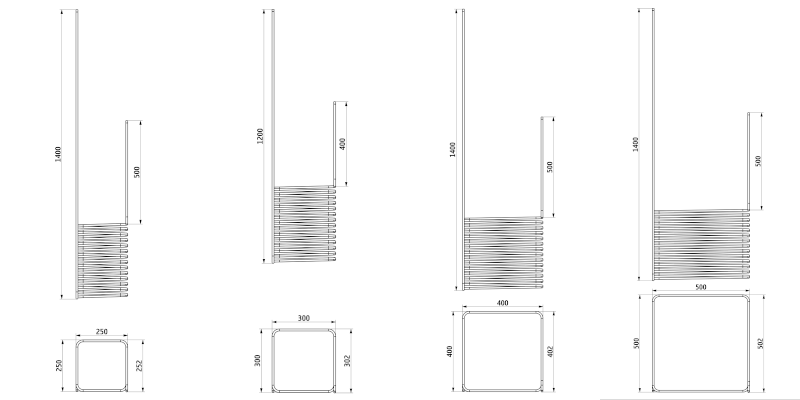

MUST COOLING COILS

| DIMENSIONS (mm) | TANK/BARREL (l) |

|---|---|

| 250x250 | 50-300 |

| 300x300 | 300-500 |

| 400x400 | 500-750 |

| 500x500 | 750-1500 |

THERMOSTAT

The thermostat is used to determine and maintain the temperature in the tank.

SOLENOID VALVE

Solenoid valve 0-7 bar or 0-10 bar, is mounted at the inlet to the tank, and serves for the flow of water in the coil that is in the tank (barrel).